Office Building Perforated Wood Acoustic Panels / Sound Absorption Board

Szczegóły Produktu:

| Place of Origin: | Guangzhou,China |

| Nazwa handlowa: | BUNGE |

| Orzecznictwo: | ISO9001 |

| Model Number: | Perforated Acoustic Panels |

Zapłata:

| Minimum Order Quantity: | 100 Square meters |

|---|---|

| Cena: | 9/31 dollar per square meter |

| Packaging Details: | Cartons or according to customer's request. |

| Delivery Time: | 7-15 days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000 square meters per month |

|

Szczegóły informacji |

|||

| Product name: | Acoustic absorb board | Patter: | 8-8-1, 16-16-3, 16-16-6 |

|---|---|---|---|

| Size: | 600*600, 1200*600,2400*1200 mm | Finish: | Melamine, Natural Wood Veneer |

| Installation: | Aluminum keel, wood frame | Thickness: | 12 / 15 / 18 mm |

| Application: | Cinema,museum | Material: | MDF,solid wood |

| Podkreślić: | perforated wood wall panels,music studio acoustic panels |

||

opis produktu

Sound absorption board perforated acoustic panel

Description:

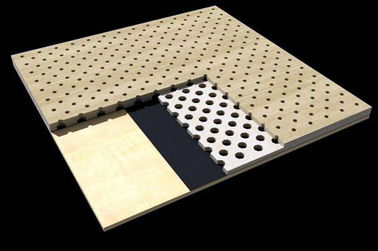

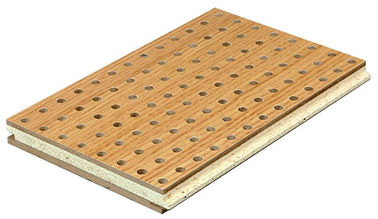

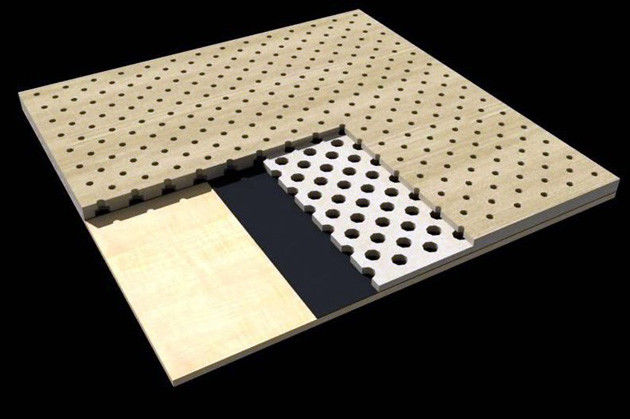

Perforated panels are the most economical way to get an acoustic treatment with a high degree of absorption. With several variations of patterns and hole diameters, different levels of absorption and aesthetic results can be achieved. Acoustic correction. Applicable to walls and ceilings.

Dimensions:

There are versions in large dimension panels for continuous walls and ceilings and also standardize ceiling panels in different versions to install with visible, semi-hidden, hidden and hidden practicable profiling.

Ceiling is usually more common to use 12 mm thick plates in standardized measures of 1200x600, 1200x300 and 600x600, although other combinations are also possible.

Technical Details:

| Material | 100% polyster fibre without chemical binders or retardants. |

| General Use | Interior decoration,Sound absorbing |

| Features | Light weight,Easy installation,Non-toxic,non-allergenic and non-irritant,Tightness and dimensional stability |

| Thickness | 12 / 15 / 18 mm |

| Specification | 600*600, 1200*600,2400*1200 mm |

| Density | 1300g/sqm,1600g/sqm,1900g/sqm,2000g/sqm |

| Installation | Pasting directly with spray,hot melt adhesive,glass glue,etc |

| Application | Meeting hall,theatre,music hall,gym,manufacturing shop,office,pub,hotel,library,reading room,classroom,kindergarten,piano room,etc |

Installation systems:

The different plates are available with different finishes depending on the type of perimeter assembly desired.

![]()

Acoustic performance:

Panels are perforated through and are typically installed with 50 mm of acoustic insulation to the rear or above. Acoustic performance varies dependent on the “open area,” with larger, or more frequent perforations providing higher performance values. Download spec sheets above for performance data on individual products.

Fleece Backing:

Non-woven, acoustically invisible fleece is typically fixed to the acoustic foam for a black-out effect in the panel opening. This fleece can be fixed to rear of panel upon request.

Installation:

(1) The warehouse to place wooden sound-absorption board needs to be sealed and damp proof.

(2) Before installation, unpacked the products at least 48 hours to make sure the environment of board and installation site is the same.

(3) The installation site should be get the ruled temperature and humidity standard at least 24 hours before installation and needs to be dry. The lowest temperature is 15 degree, the largest change range should be controlled within 40-60% after installation.

![]()

Application:

(1) Home application ( wall acoustic, ceiling sound acoustic)

(2) Entertainment application: KTV, hotel, bar, night club, disco, cinema

(3) Workplace application: office building, meeting room, office room, studio, recording room.

(4) Industrial place application: air conditioning facilities, air compressor room, manufacture workshop.